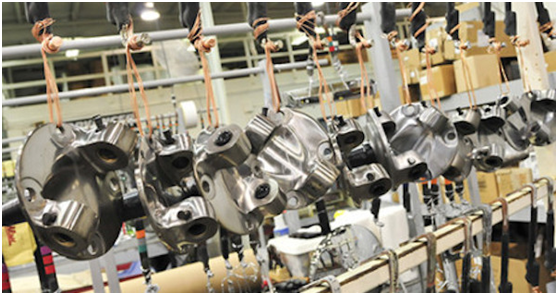

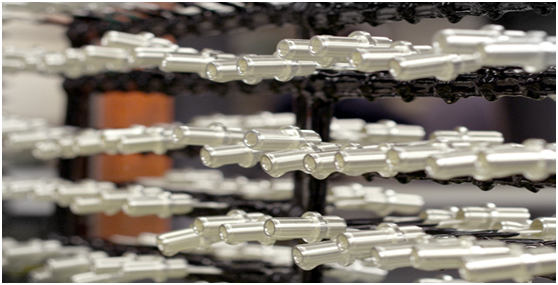

The main function of zinc plating on steel parts is to prevent corrosion, and it is the most productive plating of all electroplating qualities. Zinc-plating has the advantages of low cost, good corrosion resistance, beautiful appearance and storage resistance, and is widely used in light industry, mechanical and electrical industry, agricultural machinery, national defense and other industries.

Copper plating is often used as an intermediate layer of other coatings to improve the adhesion between surface coatings and matrix metals.

Chromium in the atmosphere can keep luster, in lye, nitric acid, sulfuric acid, and many don't react in the organic acid, chromium plating layer with high hardness and excellent wear resistance and low friction coefficient, so protective decorative chromium plating is often used in coating, prevent substrate metal rust and beautify the appearance, also often used to improve wear resistance of the product or repair the wear and tear.

The coating is used to prevent corrosion and increase conductivity, reflectivity and aesthetics. Widely used in the manufacturing industries such as electrical appliances, instruments, instruments and lighting appliances. The silver plating layer is much cheaper than gold plating, and has high conductivity, light reflectivity and chemical stability to organic acids and alkalis. Much more than gold.

The use of electrolysis or other chemical methods to attach gold to the surface of metal or other objects to form a thin layer of gold.

Professional manufacturer of asphalt machines. Our sales and R&D team have over

10 years’ experience to focus on asphalt distributor, synchronous pavement surface

vehicles and other road machinery and equipment. Based on innovation.